Rubber Coupling

HZPT GROUP CO., LTD.

About Us

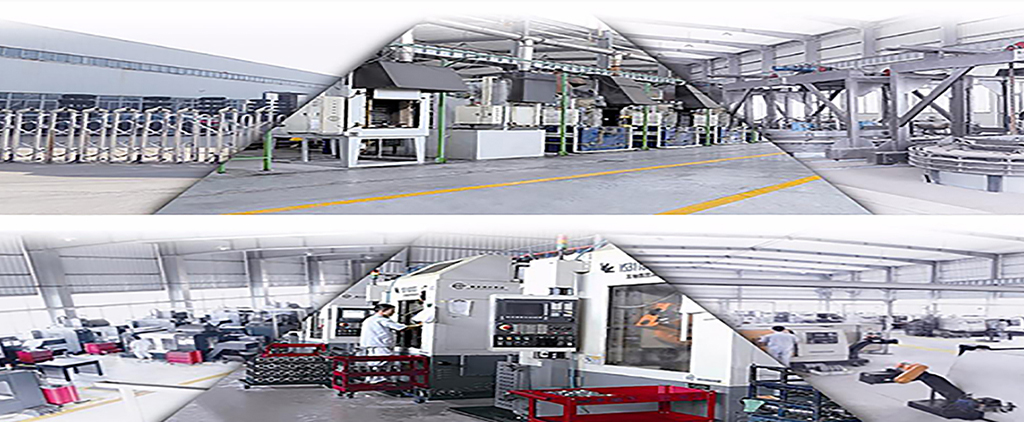

WE ARE SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS,RUBBER COUPLING, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS,RUBBER COUPLING, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID RUBBER COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS,RUBBER COUPLING, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.

WE HAVE EXPORTED OUR PRODUCTS TO CLIENTS AROUND THE WORLD AND EARNED A GOOD REPUTATION BECAUSE OF OUR SUPERIOR PRODUCT QUALITY AND AFTER-SALES SERVICE. WE WARMLY WELCOME CUSTOMERS BOTH AT HOME AND ABROAD TO CONTACT US TO NEGOTIATE BUSINESS, EXCHANGE INFORMATION AND COOPERATE WITH US.

FOR MORE DETAILS, PLEASE CHECK OUT OUR PRODUCTS CATALOGS AND MACHINE LISTS.

WE STAFF OVER 1500 WORKERS, AND HAVE CNC TURNING MACHINES AND CNC WORK CENTERS.

WE ARE ONE OF THE BEST MANUFACTURER AND SUPPLIER IN CHINA, CHOOSE QUALITY MANUFACTURERS, SUPPLIERS, EXPORTERS AT EVER-POWER.NET

20+

More than 20 years experience in research and development.

50+

Including around 50 R&D Personnel

50000+

Total factory is 50,000 square meters

tire highly flexible rubber coupling applied in the roller drive application

The rubber coupling is used for individual roller drive in which it is advisable to avoid open reduction gearing and to use a highly flexible, slack free rubber coupling and roller table geared motor. Considering all the features of this elastic rubber coupling, it has to be mentioned that the highly flexible rubber coupling’s behavior in the iron and metal industry is remarkable for the reasons stated bellow.

Buckling of the roller, which can often be seen when working conditions become heavy, has no adverse effect on the transmission part due to the rubber tire properties, being insurance for over-burdens.

Corrosion, chemicals and high temperature is not a threat for the rubber coupling, depending on the location of the highly flexible tyre rubber coupling, the rubber compound can be of chloroprene, increasing the maximum working temperature to +70 ºC, having a reliable performance and a longer functional life for hard ambient situations.

Most of the vibrations and shocks produced due to the engine start-up and the “material laid” on the roller drive process are isolated/eliminated as the rubber tire absorbs the vibrations. This tire rubber coupling is able to face inertia moments easily when machine start ups occur, decreasing the transmission of shock loads.

Flexible rubber Coupling

- Highly flexible, backlash-free tire rubber coupling

- Nominal torque range from TKN = 1,600 Nm up to 90,000 Nm with 9 sizes

- Temperature range: from –40 °C to +80 °C

Flexible and adaptable

Owing to its low torsional stiffness and damping properties the ELPEX® rubber coupling is very well suited to connecting machines with considerably non-uniform torque characteristics. Types with a fail-safe device between the flexible rings ensure emergency operation if the flexible rings are destroyed.

Your benefits at a glance

- Suitable for high dynamic loads

- Good damping properties

- Available as a fail-safe rubber coupling

- Available as a shaft and flange rubber coupling

- Designs available that comply with API 610 and API 671

Made in Germany, worldwide in use

For drives with periodically excited systems, such as

- Internal combustion engines

- Piston compressors

- Piston pumps

For drives subject to high shock loads or large shaft misalignments, for example in

- Compressors

- Excavators

- Shredders

Moreover suitable for

- Mining and Cement: tube mills, vertical mills, crushers

- Steel Production: shears, straightening machines, reversing rolling mills, pilger rolling mills

- Sugar: sugar cane mills

Rubber Disk rubber Coupling

- Highly flexible rubber coupling to connect machines with high torque fluctuations

- Nominal torque range from TKN = 330 Nm up to 63,000 Nm with 17 sizes

- Temperature range: from –40 °C to +120 °C

Flexible and adaptable

Owing to its low torsional rigidity and damping properties the ELPEX-S® rubber coupling is very well suited to connecting machines with considerably non-uniform torque characteristics. The inside diameter of the rubber disk element is vulcanized on a flange. ELPEX-S rubber couplings are designed as a flange/shaft connection or shaft/shaft connection as standard. The hub can take a taper bush.

Your benefits at a glance

- Insulates torsional vibrations with linear torsion spring characteristics

- Many kinds of flange connection are possible (including SAE)

- Easy plug-in assembly even for mounting positions that are difficult to access

- Types are available where the rubber disk element can be replaced without the need to move the coupled machines

- Overload protection for the motor and the driven machine

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

Made in Germany, worldwide in use

Used in general mechanical engineering; especially suitable for drives

- comprising internal combustion engines

- comprising piston compressors

- for cement mills

Moreover suitable for:

- Mining and Cement: tube mills, vertical mills, crushers

- Steel Production: shears, straightening machines, reversing rolling mills, pilger rolling mills

- Sugar: sugar cane mills

Rubber Tire rubber Coupling

- Highly flexible, backlash-free tire rubber coupling

- Nominal torque range from TKN = 24 Nm up to 14,500 Nm with 15 sizes

- Temperature range: from –50 °C to +50 °C for natural rubber materials, from

–15 °C to +70 °C for chloroprene rubber

Flexible and adaptable

Highly flexible ELPEX-B® rubber couplings transmit torques without circumferential backlash in machines with non-uniform torque characteristics. They are resistant to wear and maintenance-free. The hubs of the ELPEX-B rubber couplings are made of high-quality cast iron or steel. The torque is transmitted by a flexible tire reinforced with a cord ply.

Your benefits at a glance

- Compensation of very large shaft misalignments

- Independent of direction of rotation (suitable for reversing operation)

- The rubber tire can be replaced easily without the need to move the coupled machines

- Easy mounting on the shafts is possible with taper bushes

Made in Germany, worldwide in use

- Mining and Cement: crushers

- Steel Production: shears, straightening machines, reversing rolling mills, pilger rolling mills

- Power Generation: air condensers

- Chemicals and Pharmaceuticals: driers, lauter tuns, mixers, agitators, reactors

- Pulp and Paper: wastewater purification plants

- Food and beverage: lauter tuns, reactors, agitators

- Sugar: diffusers, sugar cane mills